As such, each installation is unique to the yacht on which it is fitted. When a yacht owner or builder selects SeaClean, DeAngelo Marine Exhaust begins the process of designing the complete system from turbocharger to overboard. The completed design drawings, schematics, and material specifications are then submitted to Class for design approval.

After fabrication, installation and commissioning is complete, a Class surveyor will inspect and approve the installation.

DeAngelo has successfully completed this process on close to 30 installations to date with cooperation from all major classification societies.

This depends a great deal on the rest of the exhaust system. The ideal situation is when we can design and fabricate the system from turbo outlet to overboard.

We try to obtain the greatest margin possible in order to extend filter life before cleaning is required.

We will send a technician to perform or oversee the fitting in whatever location the boat is in.

This may in some cases, actually save costs compared to using local labor.

We also send a technician to commission and fine-tune the system after installation is complete.

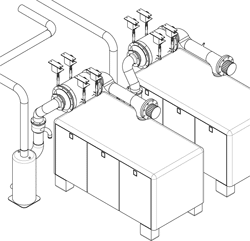

We build the control panels to fit the size and location you desire and most installations fit within the envelope of the generator sound shield with the water lift separator fit into the space between the shield and the hull.

We configure the components to fit the yacht.

Both sides may be piped differently if that is what is needed to make it fit and provide for ease of maintenance of the generator.

Power consumption varies with generator output and exhaust temperature.

We typically install a heater with a maximum output of 20kW on a 170kW generator. The full capacity may or may not be connected, depending on how the yacht operates and how the engineers manage power. The rest of the answer is included in the next question.

We use a zero crossing power controller that modulates power cycle by cycle i.e. 10kw from a 20kW heater would have the controller on for 3 cycles and off for 3 cycles with the switching occurring at the 0 voltage point of the sine wave to prevent noise spikes and harmonic generation that comes from soft starts and contactor type controls.

On system startup we have a ramping up period to prevent a sudden large load being imposed. Also, the heaters are isolated unless the generator is online and has been running for at least a minute to allow the power management system to stabilize after bringing a generator online. The power (and thus exhaust gas temperature) is regulated proportionally to the temperature of exhaust gases leaving the turbocharger. This temperature is, of course, proportional to the load on the generator.

By using this method, the SeaClean system will not place a load on shorepower when the generator is running offline such as when cooling down after switching to shore power. It does not present a parasitic load on the switchboard when large hotel loads heavily load the generator. When hotel loads are at maximum, the heater uses no power so that all power is available to the switchboard.

The number of elements depends on the wattage calculated as part of the required to obtain the correct exhaust temperature. The heater is mounted to the inlet side of the DPF.

Normal, automatic, operation provides constant and continuous regeneration across the widest possible generator load range. A high backpressure alarm output is available for integration with a yacht’s alarm and monitoring system.

Other outputs are available as options.

If greater load-bank capacity is required or desired beyond what is installed to achieve consistent filter operation, we can install larger capacity heaters in the same “envelope” so there is no space or size penalty.

We will design and install a system that provides what you need. It will be economical, and it will work. So far, the only people who have been more impressed than the engineers are the deck gang and guests.

The hull stays clean and there is no diesel smell or smoke to offend even the most sensitive nose.

New Exhaust Installation

Generator Exhaust Systems

SeaClean – Soot Filtration

Repairs & Service

Systems Engineering & Design

Parts & Accessories

Surveys & Inspections

Performance Tuning