In order to complete this project we had to undergo many modifications due to having to fit everything into a tight space while keeping it symmetrical and allowing for enough room to shape the cladding around difficult radius’s. Full credit to DeAngelo, never once did they say “no, it can’t be done”. They worked, and modified, and fabricated, until they found a way, and the end result was nothing less then perfect.

Another point that I appreciated was that there was always a continual flow of communication, I always knew exactly where they were with the project and there were never any surprises. This was very important for me as often times vendors will leave the engineers in the dark and it’s hard to pinpoint timelines when requested. In all my experiences with DeAngelo, both on my current yacht and previous ones, they have never failed to meet, and have often exceeded my expectations through their own desire and dedication to produce the very best result possible.

As a company, and as individuals, they have earned my full respect and continual desire to have them on board for any work that I might require in the future.

I am the bringer of good news today as our owner has been on for a few days and as usual, when things are going well in his life, he is full of compliments and the like. He could not stop raving about the good job done by all with ref to the exhausts.

He started by asking whether I had routed the Generator exhaust from the transom as he could hear the Genny running but could see no telltale slick as he had become accustomed too. Thought I would share this with you guys, as I felt quite proud.

It is a huge leap forward from the old system that we had and no more filters to clean and throw away at huge cost to the owner. Of course the deckies cannot stop singing the praises either as their workload around the exhaust ports are minimal compared to what it was, all the constant cleaning and stuff.

At the risk of repeating myself, we are very happy with the system and of note; bust the 2000 hr. milestone with no back pressure problems in site.

Everyone promises, and nobody seems to deliver.

My visit to SeaRacer changed all that, because the SeaClean system has been in operation for a number of months and all the smoke, soot and waterborne slicks are gone.

Our tender is kept alongside and there’s no signs of exhaust marks. If you ever have a potential client wondering if your system works, tell them to call me. Your crew thinks clean exhaust emissions are normal. And very honestly they should be.

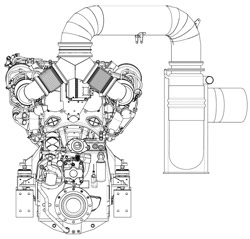

New Exhaust Installation

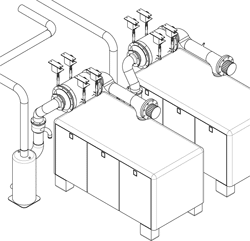

Generator Exhaust Systems

SeaClean – Soot Filtration

Repairs & Service

Systems Engineering & Design

Parts & Accessories

Surveys & Inspections

Performance Tuning